Introduction

The global energy landscape is a dynamic arena, constantly shaped by geopolitical forces, technological advancements, and the ebb and flow of supply and demand. At the heart of this intricate web lies crude oil, a resource whose uneven global distribution grants immense power to a select few major producing nations. Their output dictates not only energy markets and prices but also profoundly influences geopolitical stability. In recent years, the United States has emerged as a dominant force in this sphere, consistently breaking production records and reshaping the international oil paradigm. This blog post delves into the latest insights from the U.S. Energy Information Administration (EIA) regarding American oil production, exploring its regional concentrations, technological drivers, and the broader implications for industries reliant on specialized materials such as alloy pipe, alloy 625, and nickel alloy pipe.

EIA’s Upward Revision: A Glimpse into Future Production

The U.S. Energy Information Administration (EIA) recently released its Short-Term Energy Outlook (STEO), providing updated forecasts that underscore America’s growing prominence in the global oil market [1]. In a significant revision, the EIA has raised its projections for U.S. crude oil production (including lease condensate) for both 2025 and 2026. The latest STEO anticipates an average production of 13.53 million barrels per day (b/d) in 2025, climbing slightly to 13.51 million b/d by 2026. This marks a notable increase from the September forecast, which projected 13.44 million b/d for 2025 and 13.30 million b/d for 2026. Such upward adjustments reflect a robust and expanding domestic oil sector, signaling continued strength in U.S. energy output and reinforcing its role as a global energy supplier.

Record-Breaking Output: The Technological Edge

The year 2024 has been a landmark period for U.S. oil production, with daily output shattering previous national records, reaching an impressive 13.20 million barrels [2]. This represents a 2% increase over the record set in 2023, a testament to the nation’s innovative spirit and technological prowess. The vast majority of this growth can be attributed to advancements in hydraulic fracturing and horizontal drilling techniques, which have unlocked vast reserves previously deemed inaccessible. These sophisticated methods have revitalized mature fields and opened new frontiers, particularly across the Permian Basin, which spans parts of New Mexico and Texas. The efficiency and cost-effectiveness brought by these technologies have not only boosted production but also made U.S. oil more competitive on the international stage.

July’s Milestone: A Peak in Production

Further solidifying this trend, the EIA’s most recent STEO, published earlier this month, revealed that U.S. crude oil production in July averaged over 13.60 million b/d [1]. This figure represents the highest monthly average ever recorded, underscoring the exceptional performance of the American oil industry. The EIA stated:

“July’s production was higher than our previous estimates, which led us to raise our forecasts for U.S. crude oil production. Additionally, we increased our projections for Gulf of Mexico crude oil production because some projects are coming online faster than we anticipated.” [1]

This statement highlights not only the overall growth but also the unexpected acceleration in certain key production areas, particularly the offshore sector, demonstrating the industry’s capacity for rapid response and expansion.

Geographical Dominance: Texas, New Mexico, and the Gulf of Mexico

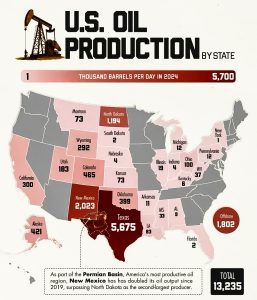

The geographical distribution of U.S. oil production reveals a clear concentration of activity in a few dominant regions [3]. Texas and New Mexico stand out as the undisputed leaders, collectively producing more oil than all other U.S. states combined. Their supremacy is largely driven by the prolific Permian Basin, a geological marvel that continues to yield substantial reserves.

Texas: The Enduring Giant

Texas remains the largest oil-producing state in the U.S., with an estimated output of 5.70 million b/d in 2024 [3]. Its long history of oil extraction, coupled with extensive infrastructure and the mature fields within the Permian Basin, provides a significant advantage. The state’s leadership in the Permian Basin’s output is a critical factor in its continued dominance, making it a cornerstone of American energy independence. The sheer volume of operations here demands constant innovation in material science and engineering.

New Mexico: The Rising Star

New Mexico has experienced a remarkable surge in oil production, doubling its output from 2019 to 2024 to exceed 2 million b/d [3]. This rapid growth is primarily due to the aggressive development of the Delaware sub-basin, a highly productive part of the Permian. The state’s strategic location and rich geological formations have positioned it as a key player in the national energy landscape, attracting significant investment and technological focus. The challenging geological conditions often encountered here necessitate robust and reliable equipment, including specialized alloy pipe.

Offshore Production: The Gulf of Mexico’s Crucial Role

Beyond land-based operations, the U.S. offshore oil production, predominantly in the Gulf of Mexico, plays an indispensable role. Contributing 1.80 million b/d, the Gulf of Mexico ranks as the third-largest producing region [3], showcasing the diversity and resilience of American energy sources. The recent faster-than-anticipated ramp-up of projects in this area further emphasizes its importance. Offshore environments present unique challenges, including extreme pressures, corrosive seawater, and harsh weather conditions, which demand materials with exceptional performance characteristics, such as nickel alloy pipe.

Other Significant Contributors

While Texas and New Mexico dominate, other states and regions also make substantial contributions [3]:

- North Dakota: As the primary producer from the Bakken Formation, North Dakota contributes 1.20 million b/d. The extreme cold and unique geology of this region require specialized equipment and materials.

- Colorado, Alaska, and Oklahoma: These states also have significant production, though their individual outputs are less than half of North Dakota’s. Each of these regions presents its own set of environmental and operational challenges, driving the need for diverse material solutions.

The Industrial Backbone: Connecting Oil Production to Specialized Materials

The sheer scale and technological sophistication of U.S. oil production necessitate a robust industrial supply chain, particularly for high-performance materials capable of withstanding extreme conditions. The processes involved in hydraulic fracturing, horizontal drilling, and transporting crude oil from challenging environments demand specialized piping and components. This is where materials like alloy pipe, alloy 625, and nickel alloy pipe become indispensable, forming the very backbone of modern oil and gas infrastructure.

Alloy Pipe: The Workhorse of the Oilfield

Alloy pipe is a fundamental component in oil and gas infrastructure, used extensively in drilling, extraction, and transportation. Its enhanced strength, corrosion resistance, and ability to operate under high pressures and temperatures make it superior to standard carbon steel in demanding applications. From well casings and drill pipes that descend thousands of feet into the earth, to flowlines and pipelines that traverse vast distances across varied terrains, the reliability of alloy pipe is paramount to ensuring efficient and safe operations in the oil and gas sector. The relentless pursuit of deeper, more complex reserves, such as those found in the Permian Basin or deep offshore, only amplifies the need for advanced alloy pipe solutions that can withstand increasingly harsh conditions. These pipes are engineered to resist sulfide stress cracking, general corrosion, and erosion, ensuring long-term integrity and minimizing environmental risks.

Alloy 625: Engineered for Extremes

For the most aggressive and corrosive environments encountered in oil and gas production, alloy 625 stands out as a material of choice. This nickel-chromium-molybdenum alloy exhibits exceptional resistance to a wide range of corrosive media, including seawater, acids, and chlorides, even at elevated temperatures. Its high strength, excellent fatigue resistance, and superior fabricability make it ideal for critical components such as risers, subsea manifolds, heat exchangers, and other equipment exposed to harsh downhole or offshore conditions. In particular, its resistance to pitting and crevice corrosion is crucial in marine and sour gas applications. The increasing complexity of extraction, particularly in sour gas applications or deepwater projects in the Gulf of Mexico, drives the demand for materials with the unparalleled performance of alloy 625. Its application ensures operational continuity and safety in environments where failure is not an option.

Nickel Alloy Pipe: Ensuring Longevity and Safety

Nickel alloy pipe encompasses a broad category of materials known for their superior corrosion resistance, high-temperature strength, and durability. Beyond alloy 625, other nickel alloys are crucial for various applications within the oil and gas industry, especially where longevity, safety, and regulatory compliance are non-negotiable. These pipes are vital for transporting highly corrosive fluids, handling high-pressure steam in processing plants, and in refining facilities where chemical resistance is paramount. The investment in robust nickel alloy pipe ensures the integrity of infrastructure, minimizes downtime due to material failure, and ultimately contributes to the environmental safety and economic viability of oil production operations. As the U.S. continues to push the boundaries of oil extraction, exploring new depths and more challenging geological formations, the demand for reliable and high-performance nickel alloy pipe solutions will only grow. These materials are not just components; they are critical enablers of advanced energy production.

Conclusion: A Future Shaped by Innovation and Quality Materials

The U.S. oil production narrative is one of remarkable growth, driven by continuous technological innovation and the strategic development of prolific basins. The EIA’s revised forecasts paint a picture of sustained high output, solidifying America’s role as a global energy leader. This robust production environment, however, is inextricably linked to the quality and performance of the industrial materials that underpin it. The demanding conditions of modern oil and gas extraction—from the high pressures of hydraulic fracturing to the corrosive environments of offshore drilling—underscore the critical need for advanced material solutions.

For companies like sztubeplus.com, specializing in high-quality alloy pipe, alloy 625, and nickel alloy pipe, this presents a significant opportunity to partner with an industry that values precision, durability, and reliability. We understand that the integrity of your operations depends on the materials you choose. Our commitment is to provide products that not only meet but exceed the stringent requirements of the oil and gas sector. By leveraging our expertise and advanced manufacturing capabilities, we ensure that our alloy pipe, alloy 625, and nickel alloy pipe solutions contribute to safer, more efficient, and more sustainable energy production. As the industry continues to evolve, demanding materials capable of enduring ever more challenging conditions, the need for reliable, high-performance solutions becomes paramount. Partnering with a trusted supplier that understands these intricate demands is not just a choice but a strategic imperative for success in the dynamic world of oil and gas. We are committed to providing the superior materials that empower the energy sector to meet its ambitious production goals, safely and efficiently. Explore our range of high-performance alloy pipe, alloy 625, and nickel alloy pipe solutions today and discover how we can support your critical projects. Visit www.sztubeplus.com to learn more about our products and how we can help you achieve operational excellenc