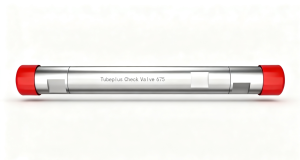

In September, a key oilfield operator hit us with an urgent demand: design and manufacture a chemical injection check valve that could extend well production life through flawless delivery of harsh chemicals in extreme high H2S/CO2 environments—all while eliminating leak risks via verifiable connection integrity.

We stepped up.

By selecting premium sour-service alloys and engineering a dual-check system (one hard seat + one soft seat), we delivered a valve dependable by design for HP/HT wells. This beast handles tubing from 2-3/8” to 7”, pressures up to 15,000 psi, and temperatures to 450°F—injecting into production tubing, injection lines, or the annulus without compromise.

Why It Excelled in the Field:

Redundant sealing: Primary + backup metal-to-metal ferrules for zero-leak connections

Sour environment ready: Full material range for extreme H2S/CO2 reservoirs

Installation-proof: Optional burst discs + externally testable connections to slash rig downtime

Tunable performance: Custom cracking pressures for precise chemical flow

Result? First-run field validation passed with flying colors. The client confirmed: “Delivered on time, zero failures, integrity verified.”

When reliability in high-pressure chemical injection is non-negotiable, our HP/HT check valves prove performance under pressure—every time.