We strive to ensure every product meets the highest levels of reliability, performance, and compliance

- Home

- /

- QUALITY CONTROL

Incoming material inspection

This critical process ensures materials meet specifications and quality standards. QA/QC teams verify supplier documentation (material certs, ASTM/ASME compliance), perform dimensional checks (diameter, wall thickness), and inspect for surface defects (cracks, corrosion). Non-destructive (ultrasonic/eddy current) or destructive testing (tensile, hardness) may validate integrity. Non-conforming materials are quarantined, and traceability is maintained to prevent defects, ensuring only compliant materials enter production.

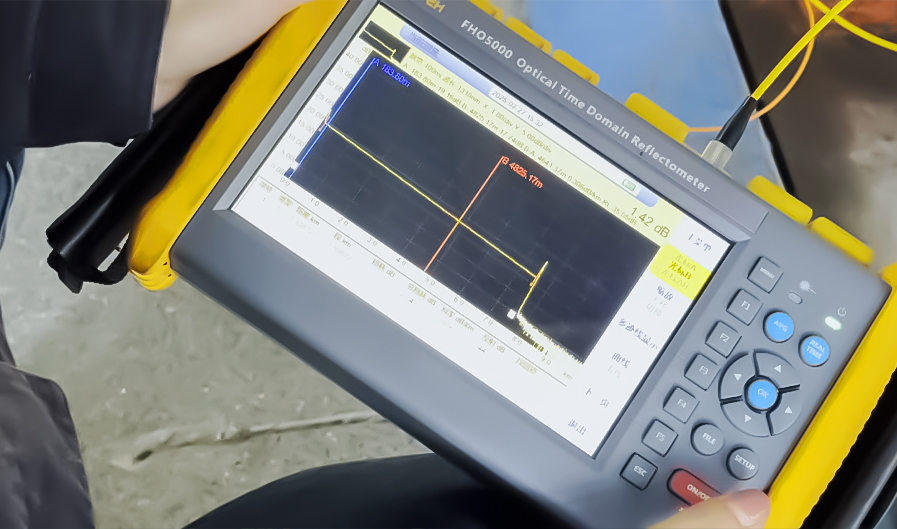

Online detection

Online detection systems ensure real-time quality monitoring during production, minimizing defects and enhancing consistency. Advanced technologies such as automated vision systems, laser profilometry, and ultrasonic sensors are integrated into the production line to continuously measure critical parameters (e.g., dimensional accuracy, wall thickness uniformity, surface flaws). Real-time data analytics enable instant identification of deviations from specifications (ASTM/ASME/ISO), triggering automated alerts or process adjustments. Non-destructive testing (NDT) methods, including inline eddy current or spectroscopic analysis, may validate material composition and structural integrity without halting production. This proactive QA approach reduces scrap rates, ensures traceability, and supports compliance by linking detection data to quality management systems (QMS) for corrective actions and reporting.

Final inspection

This phase ensures products meet customer specifications and regulatory standards before shipment. QA/QC teams perform comprehensive checks, including visual inspections for surface defects (cracks, dents), dimensional accuracy (diameter, wall thickness, straightness) using calibrated tools, and functional tests (pressure resistance, hardness). Non-destructive testing (NDT), such as ultrasonic or eddy current, identifies hidden flaws. Inspection records, material certificates, and compliance with ASTM/ASME/ISO standards are validated for traceability. Non-conforming units are isolated, analyzed for root causes, and addressed through corrective actions. Final approval certifies products are defect-free, compliant, and ready for delivery, ensuring quality assurance and customer satisfaction.

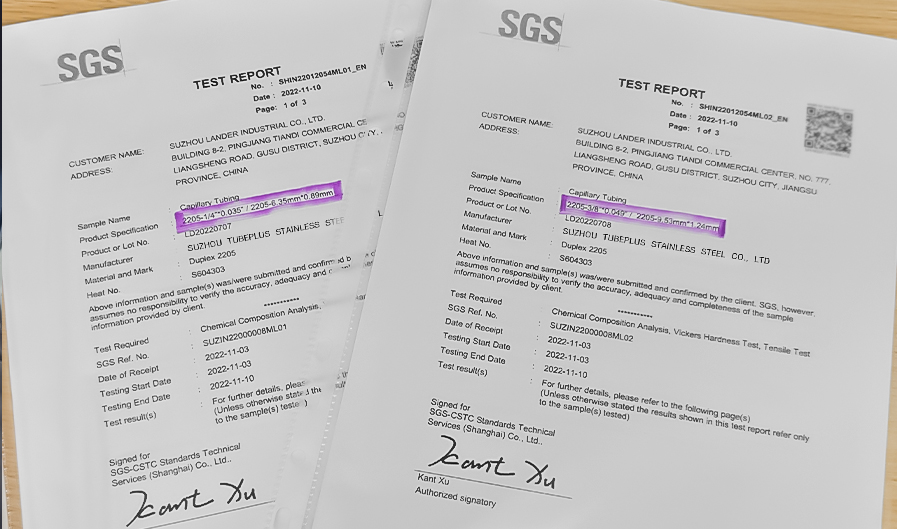

Third party testing

Third-party testing provides independent validation of product quality and compliance with industry standards (e.g., ASTM, ASME, API) or client-specific requirements. Accredited laboratories or certification bodies (e.g., TÜV, SGS, Lloyd’s Register) conduct unbiased assessments, including material composition analysis, mechanical property testing (tensile strength, hardness), and non-destructive examinations (ultrasonic, radiographic). Critical performance tests, such as hydrostatic pressure testing or corrosion resistance evaluations, may also be performed. Third-party inspectors verify traceability documentation, review manufacturing processes, and issue certified test reports or compliance certificates. This ensures transparency, mitigates quality risks, and enhances market credibility. Non-conformities trigger corrective actions with suppliers, ensuring final products meet global regulatory and contractual obligations.

Please send your RFQ

Please leave your phone number and Email address, we will contact you as soon as we can.

Seamless Pipe

Seamless pipes are bundled and securely strapped, with protective covers on pipe ends to prevent damage during handling and transportation. Packaging can be adjusted based on shipment and project requirements.

Welded Pipe

Welded pipes are packed in reinforced bundles or frames to maintain straightness and surface integrity. End protection and labeling are applied for safe export delivery.

Seamless Tube

Seamless tubes are carefully bundled or boxed with internal protection to avoid deformation and surface damage, suitable for long-distance transportation.

Capillary & Encapsulated Tube

Capillary and encapsulated tubes are typically supplied in coils or spools, wrapped with protective materials to prevent bending, contamination and mechanical damage during transit.

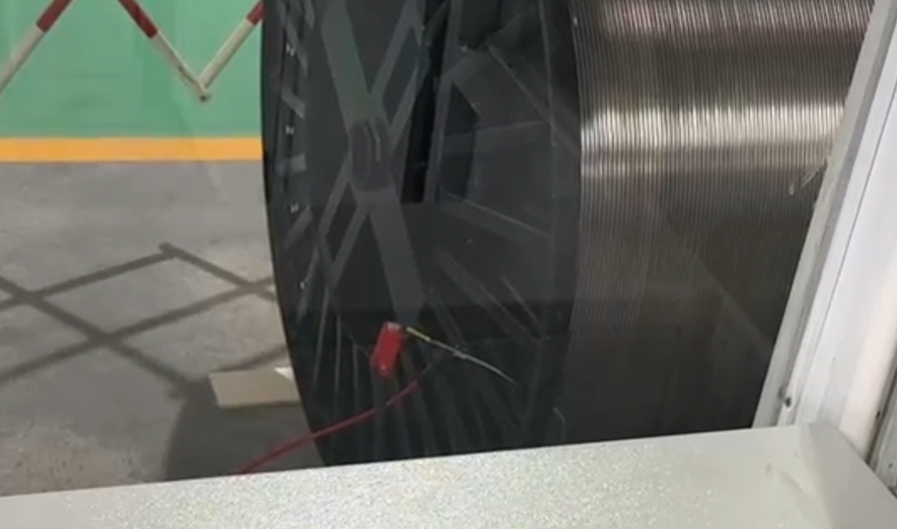

Coiled Tubing

Coiled tubing is supplied on steel reels or drums, securely fixed to ensure stability and ease of handling during storage and transportation.

Tube Fittings

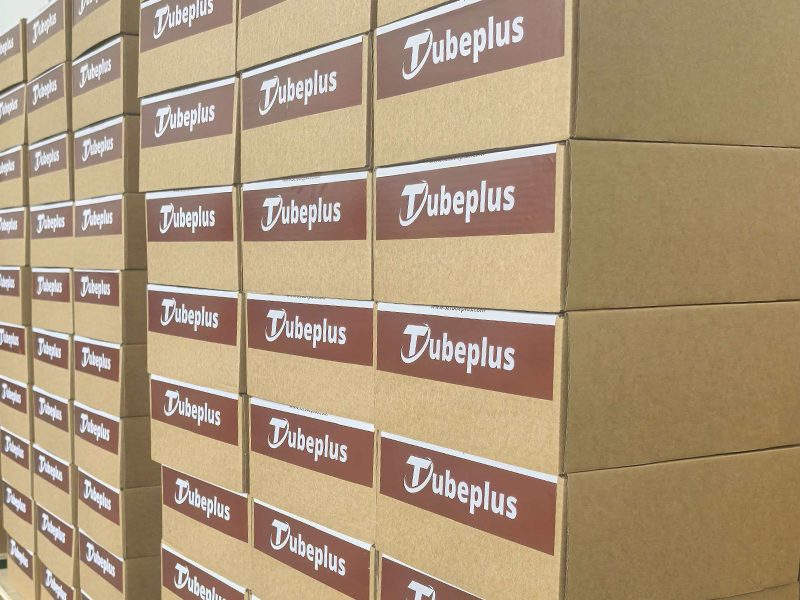

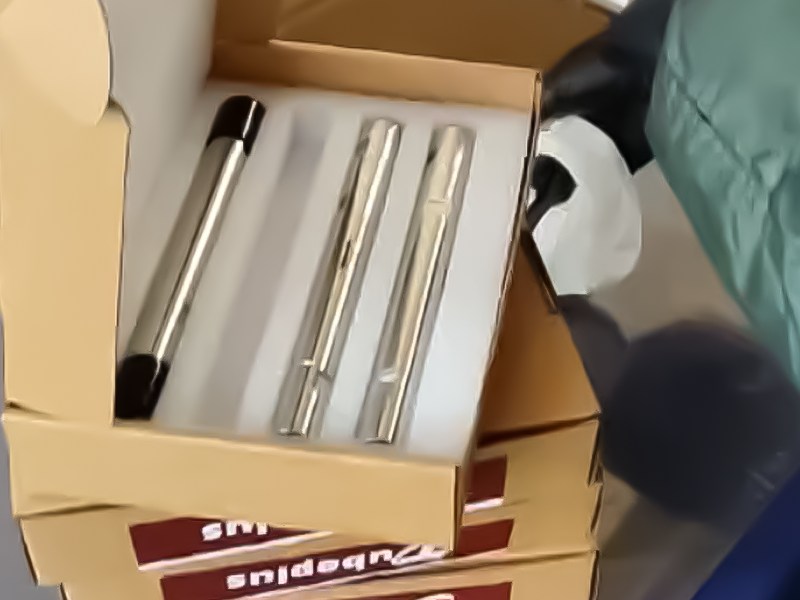

Tube fittings are individually packed or grouped in protective boxes, with clear labeling to ensure easy identification and safe delivery.

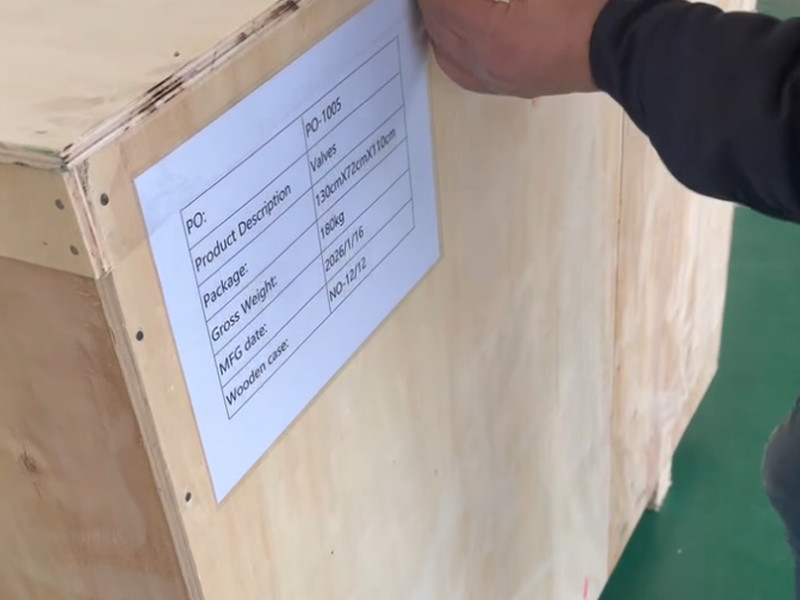

Valves

Valves are packed in wooden cases or reinforced cartons with internal cushioning to protect sealing surfaces and key components during shipment.

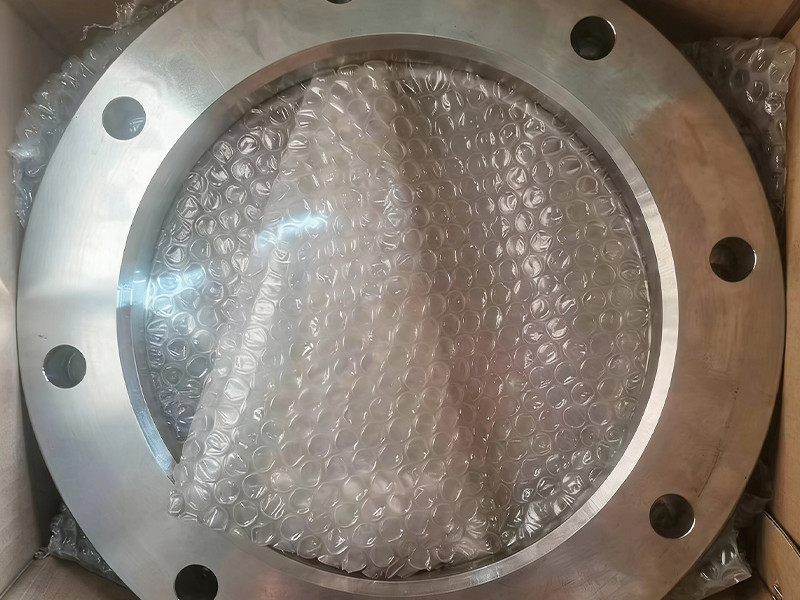

Flanges

Flanges are packed in wooden cases or pallets, with protective coatings and separation layers applied to prevent corrosion and surface damage.