| Alloy 800 (UNS N08800) | |||||||||

| Summary | A nickel-chromium alloy with good strength and excellent resistance to oxidation and carburization in high-temperature atmospheres. It also resists corrosion by many aqueous environments. The alloy maintains a stable, austenitic structure during prolonged exposure to high temperatures. Used for process piping, heat exchangers, carburizing equipment, heatingelement sheathing, and nuclear steam-generator tubing. | ||||||||

| Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

| Chemical Composition Wt,% | Min | Max. | Min. | Max. | Min. | Max. | |||

| Ni | 30.0 | 35.0 | Cu | 0.75 | C | 0.1 | |||

| Cr | 19.0 | 23.0 | Co | Si | 1.0 | ||||

| Fe | 39.5 | Al | 0.15 | 0.6 | P | ||||

| Mo | Ti | 0.15 | 0.6 | S | 0.015 | ||||

| Nb | Mn | 1.5 | N | ||||||

| Physical

Constants |

Density,g/ |

||||||||

| Melting Range,℃ 1357-1385 | |||||||||

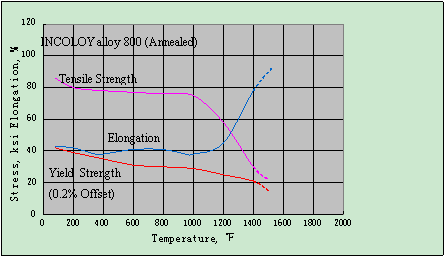

| Typical Mechanical Properties | (Annealed)

(1000h) Rupture Strength (1000h) ksi Mpa 1000℉/540℃ 48 360 1100℉/595℃ 32 160 1200℉/650℃ 21 50 1300℉/705℃ 11 18 |

||||||||

|

Microstructure

Alloy 800 is an austenitic, solid-solution alloy with a face-centered cubic structure. Titanium nitrides, titanium carbides, and chromium carbides normally appear in the alloy’s microstructure.

Characters

Alloy 800H is characterized by:

Good creep-rupture properties at temperatures above 600℃ (1110℉) without loss of ductility during long-term use at temperatures below 700℃ (1290℉), due to the limitation of (Ti+Al) content to a maximum of 0.7%;

Good resistance to reducing, oxidizing, and nitriding atmospheres, as well as to environments alternating between reducing and oxidizing conditions;

Excellent metallurgical stability in long-term high-temperature applications.

Alloy 800HT is characterized by:

Excellent creep strength at temperatures above 700℃. However, for applications where frequent excursions below 700℃ cannot be excluded, or if parts of the material are permanently exposed to temperatures below 700℃, the use of Alloy 800H is recommended;

Good resistance to reducing, oxidizing, and nitriding atmospheres, as well as to environments alternating between reducing and oxidizing conditions;

Excellent metallurgical stability in long-term high-temperature applications.

Corrosion Resistance

Alloy 800, like many austenitic stainless steels, can be sensitized, or made susceptible to intergranular attack in some aggressive media, by exposure to the temperature range of 540-760℃ (1000-1400℉).

Application

For services below 600℃, the use of soft annealed Alloy 800 is suggested. Alloy 800 is used in furnace components and equipment, petrochemical furnace cracker tubes, pigtails and headers, and sheathing for electrical heating elements.

We have products:

ASTM B407 / B829 Inc 800 / 800H / 800HT Nickel Alloy Seamless Pipe; ASTM B670 Alloy 718 / N07718 Nickel Allloy Sheet / Strip; Alloy 601 / 625 / 718 Class300 Nickel Alloy Socket Welding Flange For Medical Tube; ASTM A564 Alloy 800 / UNS N08800 Nickel Alloy Slip On Flange; Alloy 825 / 718 Nickel Alloy Steel Sheet For Gas And Oil Industry; Stainless Steel Welding Heat Exchange Tube ASTM A213 For Air Condenser; S31803 Duplex Steel Heat Exchanger Tube With Annealed&Pickling Surface; Petroleum Refining Used S31803/32750 Heat Exchanger Tube; 25.4mm Cold Rolled S31803 Tube Desalination Used Duplex Steel For Heat Exchanger; Cold Rolled Nickel Alloy Heat Exchange Seamless U Tube With Annealed; Heat Exchange Tube Nickel Alloy 625/825 For Chemical Equipment with BA/AP Surface; Nickel Alloy Cold Rolled Heat Exchange Tube Alloy 625/UNS N06625 For Pressure Vessel; 19.05mm Cold Rolled U Bend Tube Nickel Alloy Seamless For Heat Exchanger; Chemical Equipment Used 31.8mm Cold Rolled Nickel Alloy Straight/ U Bend Tube Corrosion Resistance; Alloy 400/600 Nickel Alloy Heat Exchanger U Bend Tube With Annealed Surface; Nickel Alloy Tube Seamless ASTM B407 / B829 Inc Alloy 800 / 800H / 800HT Tube; 600 / 825 / 800 Nickel Alloy Spring Wire with High Mechanical Properties; Incoloy 800/800H/800HT Pipe Fittings;