| Alloy K-500(UNS NO5500) | |||||||||

| Summary | A precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of alloy 400 with greater strength and hardness. It also has low permeability and is nonmagnetic to temperatures as lowas -101°. Used for pump shafts, oil-well tools and instruments, doctor blads and scrapers, springs, value rim, fasteners, and marine propeller shafts. | ||||||||

| Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

| Chemical Composition Wt,% | Min | Max. | Min. | Max. | Min. | Max. | |||

| Ni | 63.0 | Cu | 27.0 | 33.0 | C | 0.18 | |||

| Cr | Co | Si | 0.5 | ||||||

| Fe | 2.0 | Al | 2.3 | 3.15 | P | ||||

| Mo | Ti | 0.35 | 0.85 | S | 0.01 | ||||

| W | Mn | 1.5 | N | ||||||

| Physical

Constants |

Density,g/ |

||||||||

| Melting Range,℃ 1315-1350 | |||||||||

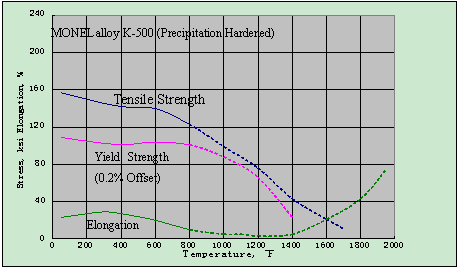

| Typical Mechanical Properties | (Precipitation Hardened)

Tensile Strength, ksi 160 Mpa 1100 Yield Strength (0.2% Offset),ksi 115 Mpa 790 Elongation, % 20

|

Microstructure

Alloy K-500 is derived from the MONEL nickel-copper composition by adding aluminum and titanium. It retains a face-centered cubic (FCC) structure. During age-hardening, a submicroscopic gamma prime (Ni₃Al) phase is formed throughout the matrix, significantly enhancing its strength and hardness.

Characteristics

Excellent corrosion resistance in a wide range of natural and chemical environments.

High resistance to chloride-ion stress-corrosion cracking.

2 to 3 times higher mechanical properties than Monel 400 after age-hardening.

High tensile strength up to approximately 650°C.

Good corrosion fatigue resistance, making it ideal for marine applications.

Low magnetic permeability and remains non-magnetic down to -135°C.

Corrosion Resistance

Similar corrosion resistance to Alloy 400, with excellent performance in environments ranging from pure water to mineral acids, salts, and alkalis.

Virtually immune to chloride-ion stress-corrosion cracking.

May be susceptible to stress-corrosion cracking in aerated hydrofluoric acid vapor under high stress.

Good resistance in high-velocity seawater and marine atmospheres, though pitting may occur in slow-moving or stagnant seawater.

Excellent resistance in sour-gas environments, making it suitable for oil and gas applications.

Applications

Alloy K-500 is widely used in the marine, chemical, petrochemical, and shipbuilding industries due to its strength and corrosion resistance. Common applications include:

- Marine components – Valve seals, pump sleeves, and wear rings for high strength and seawater resistance.

- Industrial tools – Doctor blades and scrapers.

- Fasteners – Bolts used in marine atmospheres and tidal waters, offering high resistance to chloride environments.

- Towing cables – Armor for towing cables, providing high strength, non-magnetic properties, and seawater resistance.

- Oil and gas drilling – Non-magnetic drill collars, valves, and instrumentation sleeves for resistance to chloride-containing media and sour-gas environments.

- Springs – Corrosion-resistant springs for various industrial applications.

- Aerospace components – Aviation instruments requiring non-magnetic properties.

We have products:

Alloy K500 / UNS N05500 Nickel Alloy Tube For Oil And Gas Industry; Alloy 556 / UNS R30556 Nickel Alloy Seamless Tube For Boiler; ASTM B725 / ASME SB725 Alloy K500 / UNS N05500 Nickel Alloy Welded Tube; ASTM B622 / B619 Alloy G-30 / UNS N06030 Nickel Alloy Pipe; Alloy K500 / UNS N05500 Nickel Alloy Pipe For Oil And Gas Industry; PN150 ASTM A366 Alloy K500 / UNS N05500 Nickel Alloy Socket Welding Flange; Alloy K500 / UNS N05500 ASTM B163 / B165 Seamless Nickel Alloy Tube With Eddy Current;